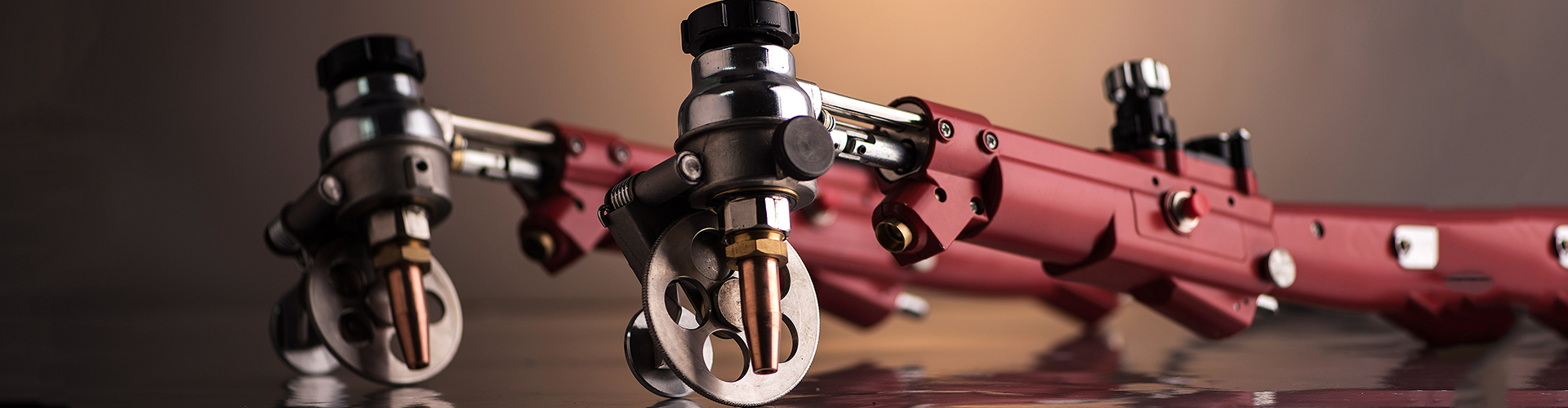

The Koike KC-72T cuts various types of steel including channel, curved plate and angled steel members and the like.. it is very compact and light, easy to manipulate, ideal for ship, vessel, dome and tank/building repair.

Features and benefits:

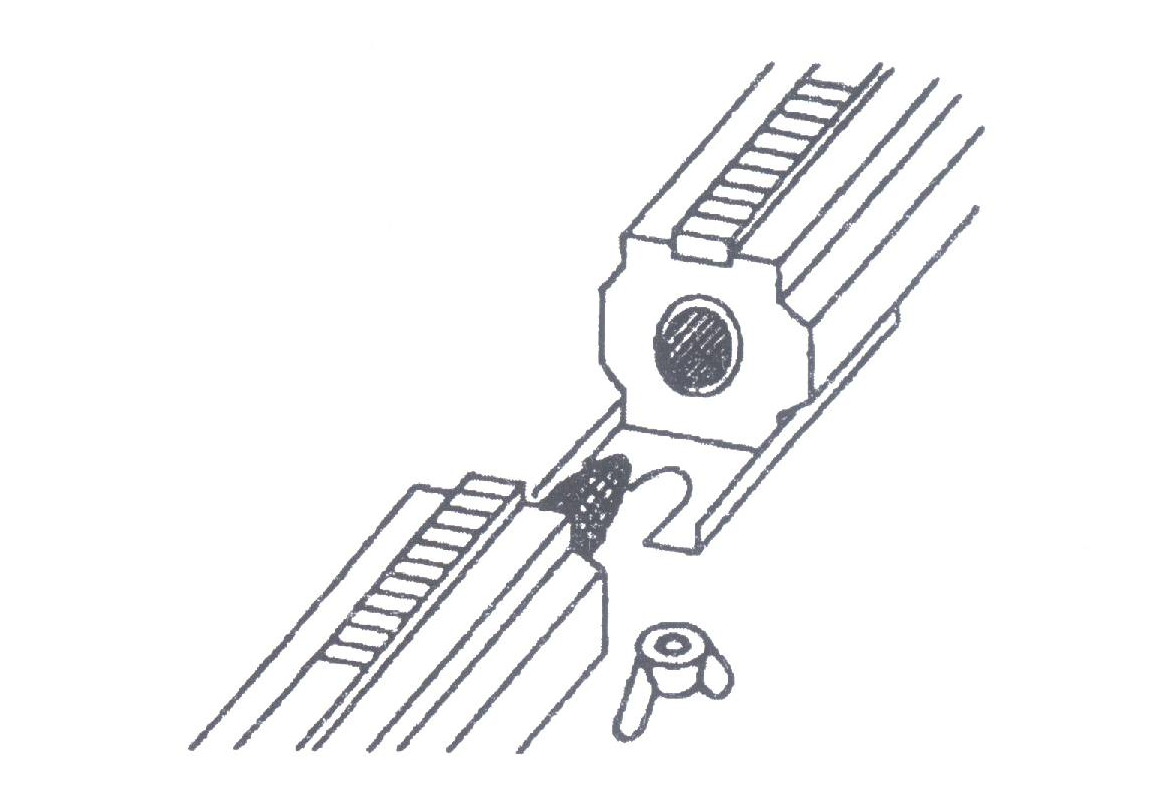

Permanent Magnet Track - Secures track to plate; allows track to be used vertically.

3D 1,000mm long, Extendable Flex Track - Make straight cuts and twisted plane cuts; extendable track allows cutting of longer parts. 2000mm (60") minimum curve radius.

Clutch Lever Releases side rollers - Allows quick positioning of machine on rail.

Application-High precision cutting for I,V application

Multi-purpose-Can be equipped different rail for multiple job application

Easy carry-Weight only 5kg and it’s easy to handle.

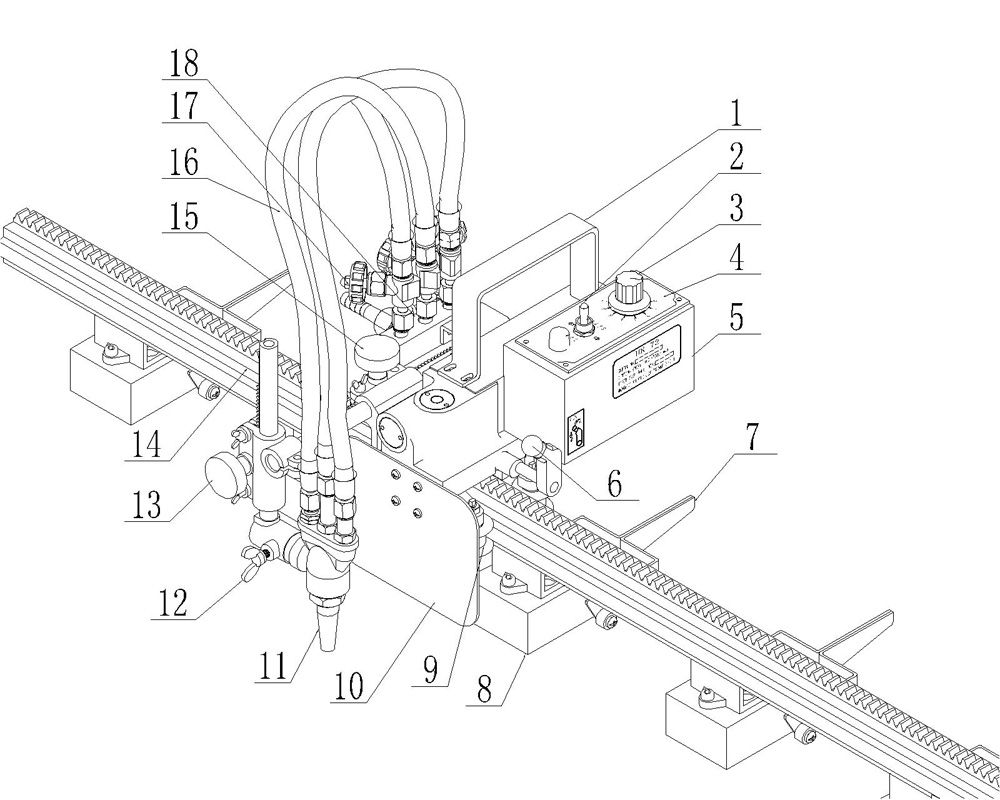

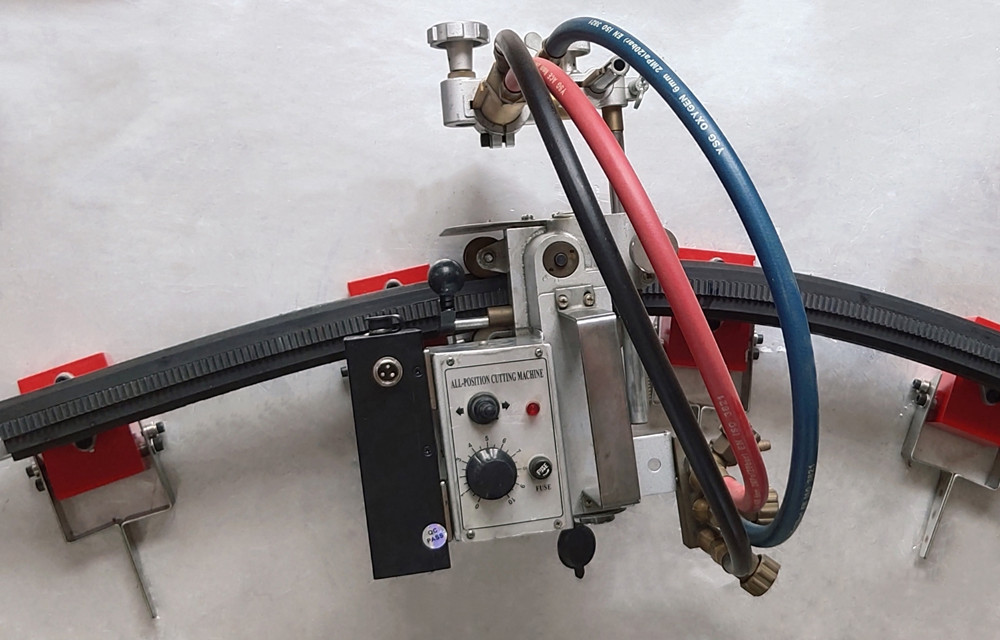

Main body configuration

1. Handle: Catch the handle when you carry machine.

2. Switch: When it is set on arrow direction, the machine starts to walk towards to this direction.

3. Speed controller: Increase the speed if it is rotated clockwise.

4. Control panel: Switch and speed controller is used to control machine.

5. Host machine

6. Clutch rod: When it is on right, the clutch is OFF. When it is on left, the clutch is ON.

7. Control rod: Use it to assemble or demount track.

8. Magnet: It fixes the track to steel plate. Use control rod to make magnet be on or off.

9. Sliding roller wheel: The wheel and track are used to keep machine stable.

10. Thermal baffle: To prevent the heat diffusing into the inner of machine.

11. torch

12. groove cutting screw13. Torch lifting knob: It is used to adjust the vertical position of torch.

14. Rubber track: There are three types: 1D――straight AL track; 2D――two-dimensional cutting track; 3D-- three-dimensional cutting track. Choose suitable track according to the sharp of work.

15. Torch sliding knob: To adjust the horizontal position.

16. Hose: Connect them between distributor and torch. The three hoses are used individually for fuel gas (red), preheating oxygen (blue) and cutting oxygen (blue).

17.valve

18. Gas distributor: It is used to control the flow of preheating oxygen, fuel gas and cutting oxygen to reach best flame.

Technical Specification

Cutting thickness |

5-50mm |

Minimum curved line length |

2000mm radius(60”) 3D rail |

Cutting speed |

150-750(mm/min)(6-30”) |

Speed control |

TRIAC variable resistor |

Drive method |

Rack and pinion |

Beveling angle |

0-45° |

Power source |

AC 110/220V, 50/60Hz |

Body Size (mm) |

190*195*140 |

Weight |

5.7kg (Main unit) 7.6kg (3D rail) |

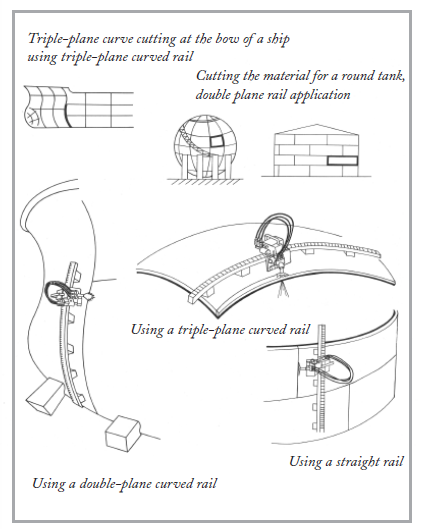

Multi-purpose Application

From flat to multi plane surfaces, the KC-72T can cut various types of steel shape, such as channel, curved thin plate, thick flat plate or vertical plate, angled steel members and the like.

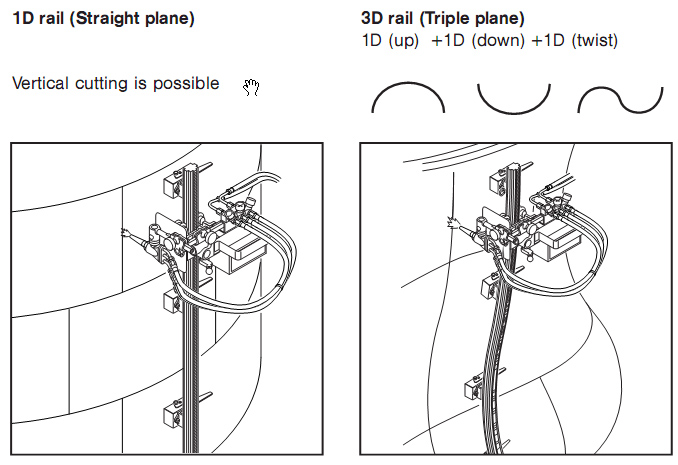

Double kinds of rails are provided for maximum job application:

1D rail (straight plane/ aluminum) 1.5m/ 10kg-with magnets

3D rail (Triple plane/rubber):1.0m/7.6kg-with magnets

Select the most suitable for the exact cutting precision requirements.

RAILS:KC-72T can be fitted with 2 kinds of rails as below:

3D rail 1000mm/pc

1D rail 1500mm/pc

Each rail can be hooked one by one at the ends for extensive length cutting.

Example:Application in shipbuilding & Vessle

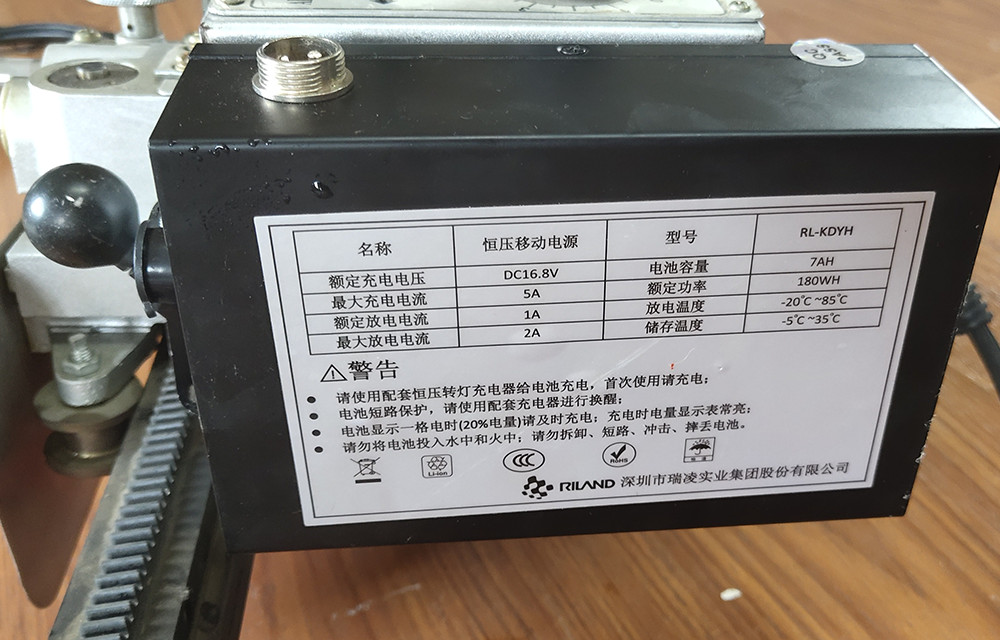

KC-72T-B Battery type

With lithium battery makes it more flexible switch between wireless power and cabled power according to the spot,the battery can work more than 8 hours continuously after full charge.

KC-72T-TWIN

The KC-72T can be revised to be fitted twin torch for the edge beveling or strip cutting.

(Model KC-72T-Twin, Standard comes with 1.5m 1D rail. Optional with 3D rail)

Welding Application

KC-72T or KC-72TB also can be convertible to welding model (KC-72W1 and KC-72W2)

Pls refer to the welding carriage sections in this catalogue for more details

KC-72T NEW TYPE

This Type is with speed-display window for more precision speed control. Rails are same as classical KC-72T.